Sunglasses

Created by GFNY cyclists for GFNY cyclists, GFNY Speed Sunglasses combine cycling-specific performance with style and innovation.

Styles

Speed frame - Alpine lens

A perfect balance of style, weight and eye protection.

Speed frame - Gruppo lens

The most complete eye coverage that minimizes contact with wind or debris to your eyes.

Speed frame - Attack lens

The lightweight option that provides eye protection from wind and UV rays but allows wind to your skin to reduce face sweat.

Sixth Avenue

If you’re obsessed with having the lightest bike and lightest gear, then these casual SIXTH AVE aviators are for you. They weigh just 20g and come in several mirror lens color for a sporty-casual look.

Features

- Ultra light – weighing in at just 26.2 grams (Attack) and 28.5 grams (Gruppo) – the lightest cycling framed eyewear on the market. You’ll forget you’re wearing them, they’re as light as air.

- Frame is made of Rilsan material, a high performance polymer of 100% renewable origin and 58% bio-based from castor plants. Use of Rilsan material combines GFNY style with an eco ethos. Rilsan is also the lightest injection mold material in existence.

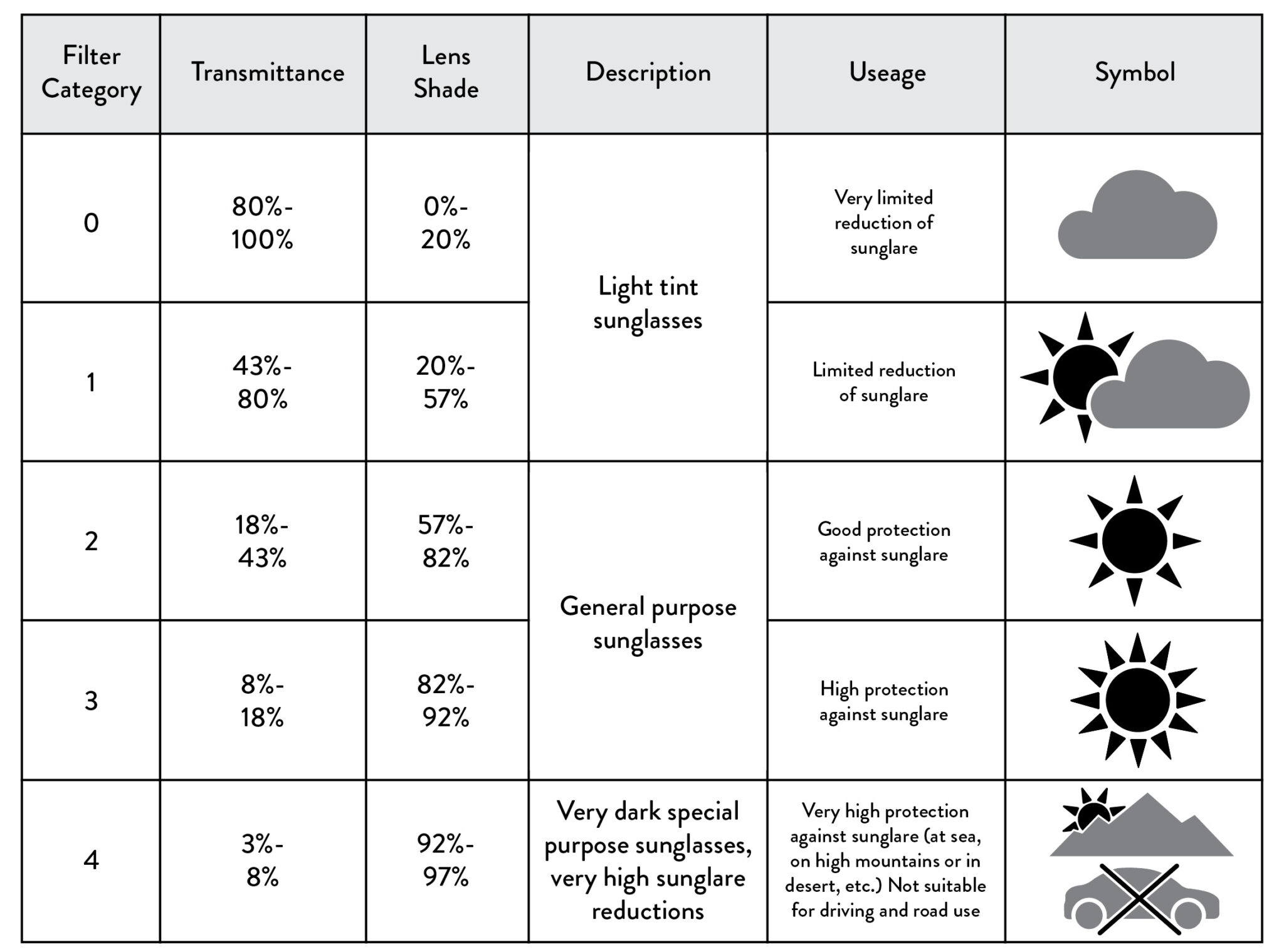

- The polycarbonate lenses are made of a premium, homogenous material that provides very good optical clarity. The material is extremely light and thin and provides important features like UV400 protection, scratch resistance, and more.

- Largest field of vision possible. The frame does not have side or lower sections to provide you unobstructed views.

- Top vents provide air flow to minimize fogging and reduce face sweat, but won't dry your eyes.

- Bendable rubber ends can be adjusted to the shape of your head for your comfort and to fit your helmet's air vents.

- Rubber nose pads adjust to provide a comfortable fit on your face.

- Drop-safe and crash-safe. The polycarbonate lenses pass each test of impact resistance and are classified as a safe material. The Rilsan frame can be dropped and can absorb impact with no damage.

- GFNY Green lenses provide excellent depth perception, enhance contrasts in tricky flat-light conditions, improve the visibility of objects and make your surroundings appear brighter.

- Italian design. Style that makes you look great.

- Italian craftsmanship. Made in Italy with the highest quality raw materials and using the best processes to make the highest quality sunglasses possible. The factory where GFNY Sunglasses are produced also produces sunglasses for many luxury eyewear brands.

Performance - Style - Innovation

Photochromic: yes / Mirror: yes / Polarized: no

Style - Innovation - Performance for Cycling and for Running

Caring for your GFNY Sunglasses

- Clean your sunglasses after every ride. If you leave dirt, sweat, minerals or sunscreen on your sunglasses even for just a few days, the dirt or chemicals will impact the coating, features and function of the lenses and may also leave marks that may affect your vision.

- Run warm water over your glasses to get rid of dust or other dirt that might scratch the lenses.

- Apply a drop of lotion-free dish soap to each lens, and rub the lenses, nose pads, frame and rubber ends with the soap.

- Rinse the soap out thoroughly.

- Shake well to eliminate as much water as possible.

- Dry the lenses with a clean microfiber cloth or lint-free towel. Microfiber cloths should be hand-washed frequently with a lotion-free dish soap and allowed to air dry.

- When not in use, keep the eyewear in its closed, original packaging in a dry place.

Making of GFNY Sunglasses

Clarity of Vision from Cyclists to Cyclists

by Chris Geiser

Ask any GFNY rider and they will tell you: GFNY apparel is designed by cyclists for cyclists. The five pockets on the jersey. The breathable fabrics. The ideal racing fit. The comfortable bib short padding. And the lifestyle apparel that reminds you that you are a rock star cyclist when you are off the bike. No pun intended, but this is all by design. That attention to detail comes from immersion in the sport at elite levels, from riding and racing all over the world, and from understanding the unique needs of cyclists. Everything from being out in the elements (the good, the bad, and the ugly), to sweating on a climb, to keeping your focus on a technical descent. Cyclists go through more variety of terrain, weather conditions, speeds, and exertion levels in a single outing than any other sport. Speaking from personal experience, dealing with fogged-up lenses on a climb or fumbling with sunglasses that don’t fit right are distractions that no cyclist wants.

They need to fit my face. They need to allow me to see without obstructions. They need to not be so heavy that they slide down my nose every five minutes. They need to not fog up. They need to fit me like my jersey fits me. And I don’t want to look ridiculous when I see a picture of myself wearing them.

You can try on hundreds of pairs. There will be some that look different. Some that look the same as the last pair you tried on. You move from pair to pair hoping that at some point form will meet function and you will have the perfect blend of how you want them to look and how you want them to fit the unique dimensions of your face. In a crowded market, it gets difficult to figure out where the unique mix of style, value and function is hiding.

Shades at the Speed of GFNY

The GFNY focus on creating a pro-style experience extends well beyond the race days. GFNY Apparel that is made by the same Italian factory that makes gear for most of the World Tour peloton is a prime example. The idea is to continue to create the kind of professional cycling gear that has features that matter specifically to cyclists. With GFNY Apparel being so popular with cyclists from around the world, GFNY Sunglasses would become the next step.

Lidia and Uli Fluhme, the founders of GFNY, searched for a long time for sunglasses for their personal use. Lidia and Uli’s testing and learning led to realizations that would later manifest themselves in requirements for developing the GFNY Sunglasses. “There was nothing that we really liked...” Lidia says, “…and we wanted something we loved ourselves, and had all the features that we wanted.”

Uli adds that other cyclists were constantly asking if he and Lidia would recommend the sunglasses they were wearing at the time. “well…. yes and no…” was the reply. “We didn’t like the glasses without frames, they felt like they might be fine for running but can’t withstand the demands of cycling. Other glasses were just too ugly in our opinion, cycling is part about riding well, but also about looking good while you ride. And other glasses felt almost insulting in that they were sold to cyclists, but were also being sold for fishing, golfing and driving. They weren’t specifically designed with cyclists in mind.”

Making it Happen

So how the heck do you get started with creating cycling sunglasses? There was only one answer. Total immersion. This started with researching and contacting factories in Italy. To be successful, the sunglasses had to have the same Made in Italy quality that GFNY Apparel is famous for.

There were some base requirements for conversations with factories. The factories had to be able to work with injection molding. A requirement for sport is that metal should not be a primary material, because of the dangers that poses in a crash for the face and brain. The injection molding would not only be more appropriate for sport use, but also be lighter. Some of the factories never replied, and some didn’t do injection molding. So, it was time to head to New York City’s eyewear industry event, the event that put all the right people under the same roof for three days. Vision East Expo is where the who’s who of the eyewear industry gather to show new products, buy new products and learn what is new and trendsetting in the optic industry.

This was an essential part of the process. Learning about how the market operates, understanding who the players are and knowing which path to choose to maintain the high standards of the GFNY brand, and the high expectations of GFNY riders and cyclists everywhere. Visiting the expo as a buyer, Lidia Fluhme was able to use this opportunity to meet manufacturers from all over the world, learn about their different approaches and start to formulate a plan for how the GFNY Sunglasses project would move forward. Talking with manufacturers, brands and middle people, there were several promising directions from some of the Asian manufacturers, particularly in Japan and Taiwan. There was also a conversation with an Italian manufacturer that were promising. The approaches were different, however, and so there were choices to be made.

On the one hand the Japanese and Taiwanese manufacturers could have something in the market quickly. In time even, for the 2017 GFNY NYC World Championship. The downside to this direction, though, was that this would be a re-use of an existing model. Branding an existing frame would allow a fast speed to market, but would be a frame that was a maybe two years old, or older, and already produced under other brand names around the world.

Lidia recalled the struggle with the decision, and how the final determination was made. “For the Italian approach, the design of the prototype would take three months, and then creating the mold would take another three months. It’s an involved process, but it’s the right process if you don’t want to bring just another generic $70 pair of sunglasses to the market. The market is flooded with these. This is not a market that we want to be in, and it’s not what the GFNY brand stands for. It always comes down to properly representing what GFNY stands for, and giving 100% of ourselves to quality. We want to do things and we want to do them right now, so it’s tough to have patience about something when we are so excited about it.”

The Italian custom design was not only the longer process, but also far more costly: the costs of creating the prototype and custom mold. To undertake the custom process, it was vital to understand the market, the audience, the design requirements and, finally, creating a trendsetting design, while still being elegant. On top of that, making sure to implement all of Lidia and Uli’s technical specifications for how the sunglasses should perform and which features they should have.

While the decision felt right, there was a lot of anxiety and anticipation surrounding the time to market. The chosen factory was fully capable of providing an injection mold, but that would take six months and be a sizeable financial commitment. The final sunglasses would be at least a year away.

While the Asian factories presented reasonable options, and very good quality, the GFNY “by cyclists for cyclists” approach demanded a higher attention to detail.

The Italian Process

The Italian factory is located in the same area that most of the high-end eyewear designers are in, just outside Milan. The core of this factory’s business is high-end, trendy sunglasses for big brands. However, they had no experience with sport. Especially cycling. The upside was that they knew what the fashion trends were, and what would look good. In hearing the requirements, the designer immediately understood the delicate balance between form and function. He understood that the eyewear needed to be the gear that a cyclist would look forward to wearing on the bike, because of how they feel, how they look, and how they perform.

Let’s remember that sunglasses aren’t an easy product to design, no matter what they are being designed for. Something that needs to fit 90% of the world’s faces. The lens size needed to be inside a specified range. The nose pads needed to be adjustable to fit various nose bridge types. The sunglasses also needed to fit various head sizes, and also fit in various helmet vents, so they needed to have bendable ends.

Uli explained that glasses for running, golfing, driving and fishing were not the same as something designed specifically for cycling. After in-depth testing, it was an easy decision to make the GFNY Sunglasses with a frame. Sunglasses without frames were too flimsy, and the frames had to be at the top to provide a maximum field of vision to the rider. But while the sunglasses needed a frame, they also had to be very light. The lightness of the frame came from two factors: the thoughtful design of the frame shape and the material to be used: TR90, the lightest engineered plastic in existence.

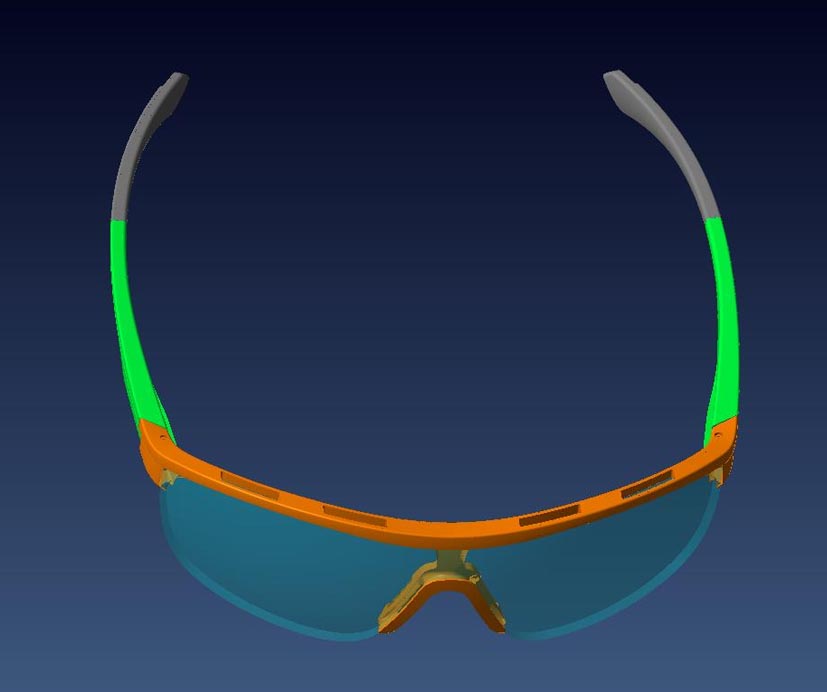

The designer was completely tuned in to the requirements. While not a cyclist himself, he worked hard to make sure that he was meeting the requirements in the three design concepts that he presented. He provided front, side, and top views for each design concept. With the second concept being the clear favorite, there were some fine-tuning details and modifications that needed to be made before the next step. Having gotten those modifications in place, it was time to do a 3D print of the sunglasses.

The 3D print was an ideal way to test the form and most of the function (with one notable exception – seeing). Uli’s perception of using the 3D model was that you had to find a way to imagine the next step and see past the prototype to what the potential in the shape and form were. “You have to have enough imagination to understand shape, and cut, and where it was positioned on the face, higher, lower, how it sat, how it wrapped around”, says Uli, “it wasn’t easy to visualize the final product based on the 3D print, but it was a necessary step to review the 3D print prior to making the mold.”

With the 3D print reviewed and approved, the mold process began. Every wake up brought the mold completion another day closer. The preparation was well worth it, but the anticipation of the completed mold was a difficult amount of time to wait.

Finally, the first samples were shipped, and it was time to test. Twelve samples were shipped, with different colors, different end-pieces, different nosepieces, different lens types and different lens shapes.

It took many rides to work through the various options. Testing on the road for what was working well, were the frames breathable, how did they do with more wind, with less wind, with sweat. Then testing the different end-pieces and nosepieces. And finally, testing the different lenses, did they allow enough airflow or not enough airflow behind the lens, and which style was, well, most flattering. Lidia and Uli were going on rides with pockets full with sunglasses, to test and compare several styles “side-by-side” during a ride.

After all the decisions were made and final production began, it was time to finish the packaging materials: the case, the pouch, the cleaning cloth, the box and the technical brochure, fulfilling the US Food & Drug Administration (FDA) standards. As part of the proprietary mold that GFNY developed, another requirement is also registering the sunglasses with the FDA and paying the substantial FDA registration fees.

The Results

Now generally available at the GFNY Online Store shop.gfny.com, the GFNY Sunglasses come in four colors (white, black, green, transparent-gray), four types of lens options (clear, mirrored, black and photochromic), and five styles (regular, NYC, Colombia, Mexico, Italy). You can select the frame color & lens type & design style combination that fits your style.

The clear lenses will get it done in any light (super handy for winter, cloudy days, or low light conditions like nighttime riding or dense forests), while the black lens & black frame style provides more of a jet-setter look, the mirrored lenses provide that super-sporty feeling that so many of us get from cycling, and the photochromic lenses can take you from pre-dawn cycling into daylight or from afternoon cycling to after dusk.

The Speed line is specifically made for cycling, while the casual line includes two models: Podium and Riviera. Both casual sunglass models were designed as an extension to your off-the-bike GFNY cyclist identity.

Sunglasses are such a personal item, especially for cyclists. The GFNY Sunglasses are designed specifically for the cycling specifications and lifestyle, and with the Be a Pro for a Day attention to detail.